With so many different subscription box companies competing for customers’ time and money, how can you craft a memorable brand experience that both retains current subscribers and attracts new ones? For the most successful subscription box companies, the box itself acts as a key brand ambassador, and investing in the right custom packaging as early as possible can be just as valuable as investing in a beautiful website. A 2013 eCommerce packaging survey by dotcom distribution revealed that nearly 40% of consumers would share a picture of a uniquely packaged online order via social media channels.

Phase I: Design & Inspiration

Once you’ve decided that you finally need to see what all the fuss is about and debut some slick premium packaging on your next batch of subscription boxes, you still have a few things to figure out. First and foremost, there’s the design! After spending hours looking at box design inspiration, you now have the perfect full-color subscription box design that embodies your brand on every inch of the cardboard. Next step — figuring out how to bring it to life!

Phase II: Sourcing

At this point, it’s time to find a custom box manufacturer, and chances are you’ll start hearing a lot of box-related jargon as you begin to research the various printing options. Cutting dies? Printing plates? Flute size? Dieline? $1500 in tooling charges with minimum orders at 1000 units? Trying to assess all of the various options and expenses can definitely be overwhelming — and stressful too when so much of your brand and money is at stake.

Fortunately, several resources are now available online that can help simplify the entire design and ordering process, so that you can avoid all of the headaches associated with traditional printing techniques and larger quantities. Some resources like Packlane even let you start with a minimum of just 10 custom printed boxes, making it easier than ever to make your subscription box debut look as polished as possible. ThePaperWorker is another supplier that leverages digital printing technology to offer low minimums on corrugated boxes with high quality printing. For basic 1-color logos printed on eco-friendly Kraft mailers, ecoenclose is another great resource to check out.

Final Tips

- For order volumes under 1000 boxes, your best bet is to go digital.

- The flute size refers to the thickness of the cardboard substrate. For most subscription boxes, E-Flute (1/16”) is perfectly sufficient and has the added bonus of better printing quality. In some cases you may want to ask your box supplier about B-Flute (1/8”), which is slightly thicker and provides added strength and protection for shipping.

- The most common subscription box style is the ‘Mailer’ style box, also known as a roll-end locking front with dust flaps, or RETT with cherry locks. Although this is the most common style, not all mailers are created equal — it may be a good idea to request a couple of samples so you can evaluate which is the best quality.

- The most common corrugated cardboard box materials are Kraft, White, or Kemi white. Kraft (brown) material tends to be the least expensive, and gives your brand more of a ‘recycled’ shipping box aesthetic. Notable Kraft subscription boxes include: Citrus Lane, Harry’s, and Nature Box. White is slightly more expensive, but often results in higher printing quality when printed digitally. Notable white subscription boxes include: Love With Food, LootCrate, and BoxyCharm. Kemi (short for Kemigraph) is a premium clay-coated substrate that results in a beautiful, glossy finish because the ink doesn’t penetrate the liner.

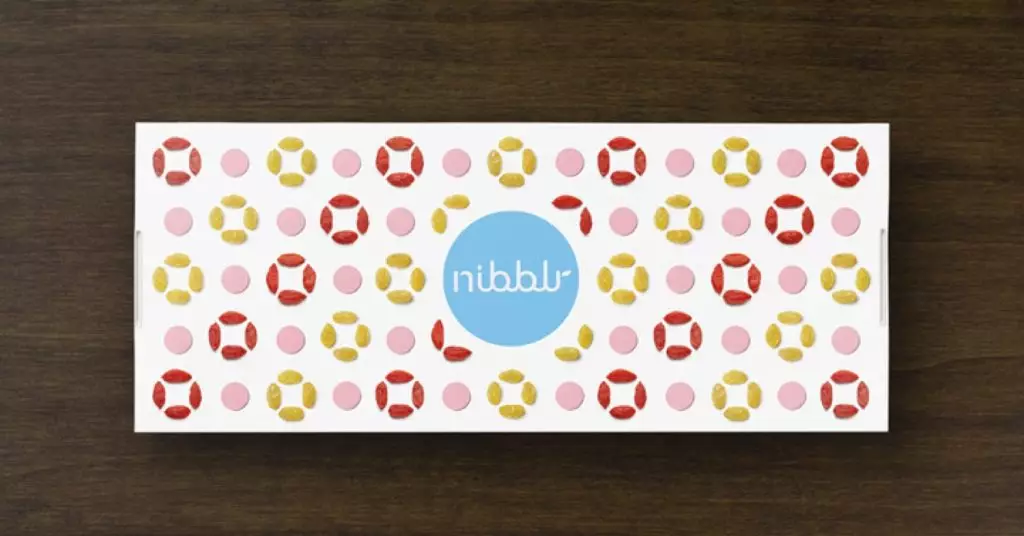

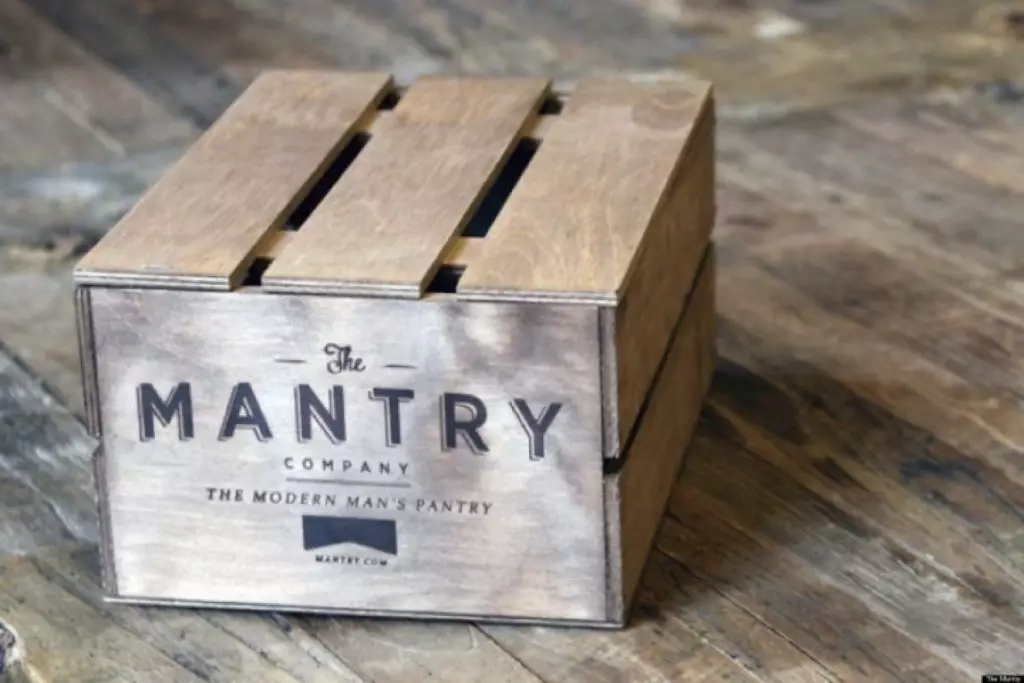

If you’ve looked into the different shipping box options and feel like you’d rather spend the cash to create a truly one-of-a-kind box design, then check out the following examples to see just how creative your subscription box packaging can be:

Start your subscription business with Subbly today. For free.